THE CHALLENGE

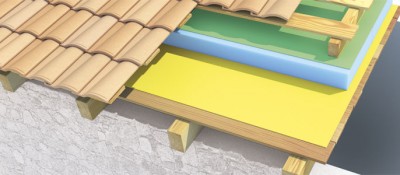

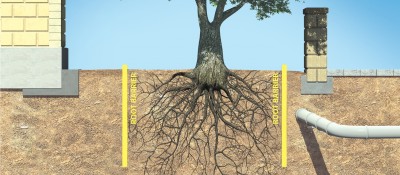

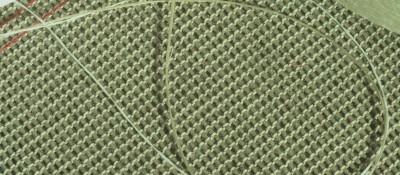

Railways are designed to carry heavy traffic loads over the train tracks. Railroads are supported over sleepers (cross-ties) that in turn rest on compacted ballast layer. Finer compacted aggregate and sandy soils rest beneath the ballast layer. If the ballast layer and the underlying soil layer are not separated with a heavy weight nonwoven geotextile fabric, the heavy traffic loads will eventually cause the breakdown of the compacted ballast layer and intermixing with the underlying soil/finer aggregates. The layers have to stay separated while at the same time, water should be allowed to pass through. Due to the sharp nature of the ballast surface texture, geotextiles used in railroad applications should possess excellent resistance to puncture; dynamic perforation resistance as well has moderate tensile elongation properties. Since the geotextile will also serve the function of filtration, it should possess a considerably small characteristic opening size to allow water to pass through without allowing the intermixing and passage of soils to the surface. In certain areas when railroad tracks are to be built, due to the weak nature of the underlying soil, the base foundation layer thickness can be reduced by using a layer or more of extruded geogrids with large apertures. The bearing pressure of the underlying foundation is increased through the interlocking action between the ballast and the geogrid layers.

THE SOLUTION

Thrace Group SNW/NW/PNW Nonwoven Geotextiles offer effective solutions by providing filtration and separation functions. The Biaxial Extruded TG geogrids offer effective solutions by providing reinforcement functions that significantly reduce foundation design thicknesses without affecting performance. The reduction in foundation thickness translates to material and labor cost savings. They are durable products that will withstand the stresses encountered during installation operations and have a proven extended lifetime performance.

THE BENEFITS

- Improved and extended lifetime performance, securing construction works

- Considerable cost savings

- Reduced CO2 emissions for environmentally friendly projects

Geogrids & Geocomposites |

|||||||||

| Product Name | Tensile Strength MD | Tensile Strength CD | |||||||

|---|---|---|---|---|---|---|---|---|---|

| TG1 | 12,4 kN/m | 19 kN/m | |||||||

| TG2 | 19,2 kN/m | 28,8 kN/m | |||||||

| TG1515 | 15 kN/m | 15 kN/m | |||||||

| TG2020S | 20 kN/m | 20 kN/m | |||||||

| TG2020L | 20 kN/m | 20 kN/m | |||||||

| TG2525 | 25 kN/m | 25 kN/m | |||||||

| TG3030S | 30 kN/m | 30 kN/m | |||||||

| TG3030L | 30 kN/m | 30 kN/m | |||||||

| TG4040S | 40 kN/m | 40 kN/m | |||||||

| TG4040L | 40 kN/m | 40 kN/m | |||||||

| TG3333L | 33 kN/m | 33 kN/m | |||||||

| TG5050S | 50 kN/m | 50 kN/m | |||||||

| TG1600 | 16 kN/m | 16 kN/m | |||||||

| TG2000 | 20 kN/m | 20 kN/m | |||||||

| TG3000 | 30 kN/m | 30 kN/m | |||||||

| TG4000 | 40 kN/m | 40 kN/m | |||||||

Nonwoven Geotextiles |

|||||||||

| Product Name | Tensile Strength MD | Tensile Strength CD | Resistance to Static Puncture | Water Flow Rate | |||||

|---|---|---|---|---|---|---|---|---|---|

| S6NW | 6 kN/m | 6 kN/m | 1050 N | 144 l/m2/sec | |||||

| S8NW | 8 kN/m | 8 kN/m | 1500 N | 130 l/m2/sec | |||||

| S10NW | 10 kN/m | 10 kN/m | 1700 N | 110 l/m2/sec | |||||

| S12NW | 12 kN/m | 12 kN/m | 2000 N | 110 l/m2/sec | |||||

| S14NW | 14 kN/m | 14 kN/m | 2300 N | 90 l/m2/sec | |||||

| S16NW | 16 kN/m | 16 kN/m | 2600 N | 90 l/m2/sec | |||||

| S18NW | 18 kN/m | 18 kN/m | 2900 N | 80 l/m2/sec | |||||

| S20NW | 20 kN/m | 20 kN/m | 3500 N | 70 l/m2/sec | |||||

| S22NW | 22 kN/m | 22 kN/m | 3700 N | 70 l/m2/sec | |||||

| S25NW | 25 kN/m | 25 kN/m | 4300 N | 65 l/m2/sec | |||||

| S30NW | 30 kN/m | 30 kN/m | 4800 N | 45 l/m2/sec | |||||

| 80NW | 6 kN/m | 6 kN/m | 860 N | 144 l/m2/sec | |||||

| 90NW | 7 kN/m | 7 kN/m | 1180 N | 137 l/m2/sec | |||||

| 100NW | 6,7 kN/m | 6,7 kN/m | 900 N | 100 l/m2/sec | |||||

| 110NW | 9 kN/m | 9 kN/m | 1600 N | 120 l/m2/sec | |||||

| 120NW | 10 kN/m | 10 kN/m | 1700 N | 110 l/m2/sec | |||||

| 140NW | 11 kN/m | 11 kN/m | 1600 N | 90 l/m2/sec | |||||

| 170NW | 13 kN/m | 13 kN/m | 2500 N | 110 l/m2/sec | |||||

| 190NW | 15 kN/m | 15 kN/m | 2600 N | 85 l/m2/sec | |||||

| 200NW | 16,7 kN/m | 16,7 kN/m | 2350 N | 60 l/m2/sec | |||||

| 270NW | 22 kN/m | 22 kN/m | 2800 N | 35 l/m2/sec | |||||

| 300NW | 25 kN/m | 25 kN/m | 4300 N | 65 l/m2/sec | |||||

| 350NW | 24 kN/m | 24 kN/m | 4400 N | 65 l/m2/sec | |||||

| 400NW | 29 kN/m | 29 kN/m | 4100 N | 18 l/m2/sec | |||||

| 500NW | 37 kN/m | 37 kN/m | 6200 N | 35 l/m2/sec | |||||

| 600NW | 43 kN/m | 43 kN/m | 7400 N | 35 l/m2/sec | |||||

| P400NW | 25 kN/m | 33 kN/m | 5000 N | 40 l/m2/sec | |||||

| P500NW | 30 kN/m | 44 kN/m | 6200 N | 35 l/m2/sec | |||||

| P600NW | 35 kN/m | 52 kN/m | 7400 N | 30 l/m2/sec | |||||

| P800NW | 45 kN/m | 75 kN/m | 10000 N | 25 l/m2/sec | |||||

| P1000NW | 60 kN/m | 95 kN/m | 11500 N | 20 l/m2/sec | |||||

| P1200NW | 67 kN/m | 105 kN/m | 14000 N | 20 l/m2/sec | |||||

| P2000NW | 100 kN/m | 150 kN/m | 25000 N | 7 l/m2/sec | |||||

| S13NW | 13 kN/m | 13 kN/m | 2100 N | 100 l/m2/sec | |||||

| P1600NW | 80 kN/m | 125 kN/m | 21000 N | 10 l/m2/sec | |||||